Mobile: 07748 563747

Office: 01344621625

Email: info@gforceascot.co.uk

Email: info@gforceascot.co.uk

Office: 01344621625

Mobile: 07748 563747

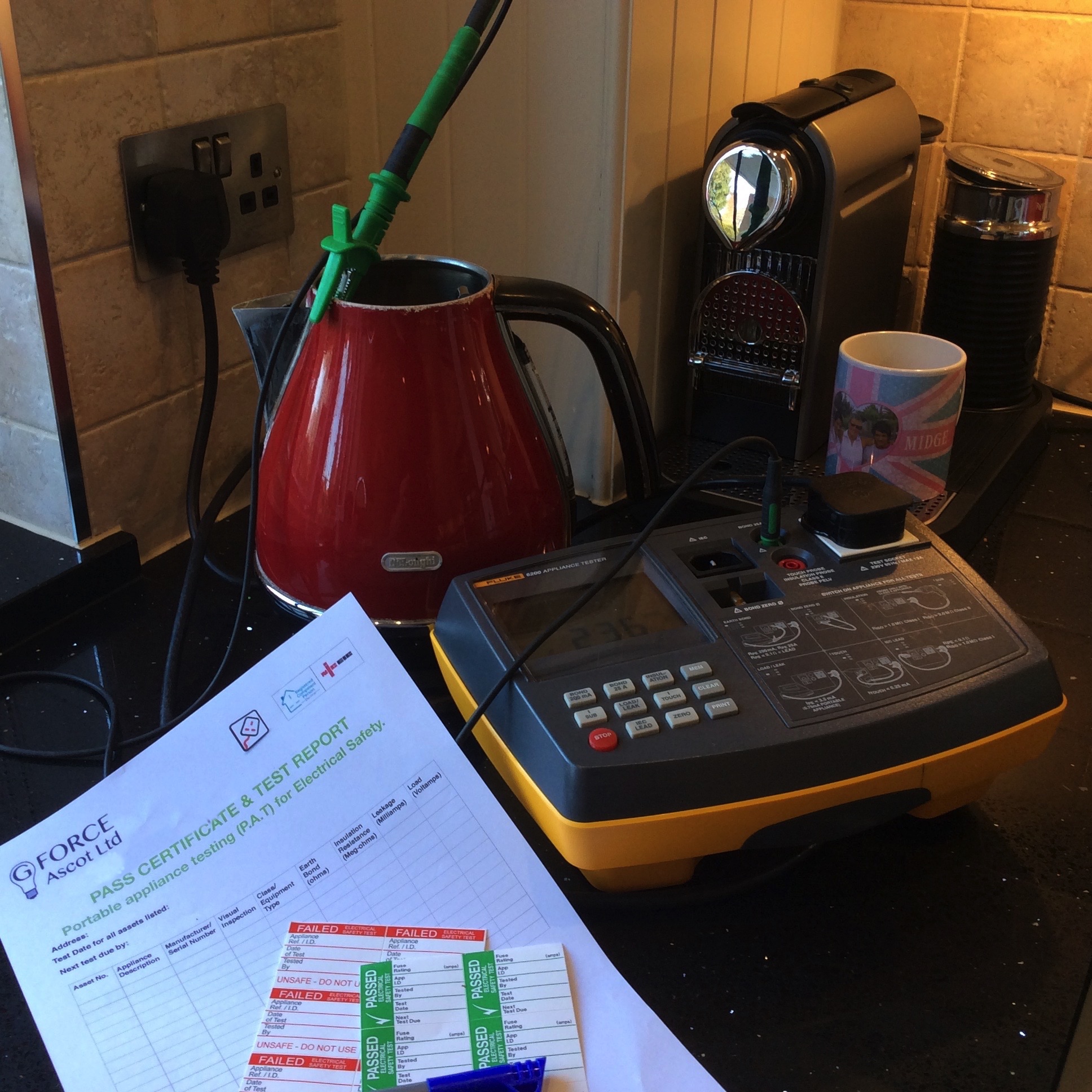

P.A.T Testing stands for Portable Appliance Testing (P.A.T). The term used to describe the examination of electrical appliances and equipment to ensure they are safe to use. Most electrical safety defects can be found by visual examination but some types of defect can only be found by testing. We are fully qualified for P.A.T. Testing and are annually assesed and included on the NICEIC 'P.A.T Testing Register'.

You need me if you are a business owner, landlord, or work as mobile photographer, DJ or caterer.

It is essential that all places of work, and those providing any category of public services comply with Health & Safety legislation.

These requirements exist to maintain a safe, working environment for each and every employee in the workplace, and to protect your customers from the risks associated with electrical appliances. Furthermore, if the necessary legislation are avoided or ignored, in the event of an incident involving an electrical appliance a company can face severe, detrimental penalties as a direct result.

Note, if leads are detachable they are tested as separate items, it would seem unfair to 'fail' an expensive piece of equipment if the fault was with an inexpensive (and more vulnerable to damage) connecting lead.

G. Force (Ascot) Ltd offers P.A.T testing services in Ascot and surrounding areas. P.A.T testing will ensure your compliance to the legislative requirement that your electrical appliances are electrically safe and fit for intended use.

We uniquely tag and identify each item we test and issue a safety certificate which is valid for 1 year for portable and handheld appliances, this may be extended to 4 years for stationary or fixed appliances . This provides peace of mind for your business, and satisfy your legal obligations under Health and Safety law.

Our P.A.T testing service is also priced highly competitively and provides a cost effective solution for businesses of all sizes.

Check my guide below, smaller appliances generally have a smaller flex and need a smaller fuse often a 3 or 5 Amp. Appliances that get hot have larger cables and usually need a larger 10 or 13Amp fuse

The calculation needed is ‘Ohms Law’. Current (Amps)= Power (Watts) divided by Voltage (Volts) - always assume to be between 230-240Volts in UK.

For example a kettle is 3KW 3000W / 240V =12.5 Amps. Always use the closest size fuse that is equal or higher than the maximum rated power of the appliance, this will ensure the fuse blows fast enough to prevent damage to the flex and appliance in the event of a fault developing. The wrong size fuse can lead to overheating.

Are you using the correct size fuse?

Domestic Appliance Fuse Size Guide:

1 Amp fuses should be used for appliances up to 240 Watts

2 Amp fuses should be used for appliances up to 480 Watts

3 Amp fuses should be used for appliances up to 720 Watts

5 Amp fuses should be used for appliances up to 1,200 Watts or 1.20 KW

7 Amp fuses should be used for appliances up to 1,680 Watts or 1.68 KW

10 Amp fuses should be used for appliances up to 2,400 Watts or 2.40 KW

13 Amp fuses should be used for appliances up to 3,000 Watts or 3.00 KW

An 'appliance test' includes the cost of the test, and the cost of the appropriate test label which includes the test status (pass or fail), the date of the test, the date of the next required test and a unique identifier that records the individual appliance record. Upon completion you will be issued full certificate which complies with the requirement to record such tests.

The requirement for P.A.T testing is covered by a number of pieces of legislation. You can link to these acts of law below.

(Please note, that the information provided by these websites is not controlled by, or the responsibility of G.Force(Ascot)Ltd:

- The Health & Safety at Work Act 1974

- The Management of Health & Safety at Work Regulations 1999

- The Electricity at Work Regulations 1989

- The Workplace (Health, Safety and Welfare) Regulations 1992

- The Provision and Use of Work Equipment Regulations 1998

The following summary of the above is taken from guidance sites online;

General legislative guidance:

This guidance has been prepared with reference to the Institution of Electrical Engineers Code of Practice for In-Service Inspection and Testing of Electrical Equipment. Although reference is made to legislation, this guide should not be considered as legal advice. In cases of doubt, the specific legislation mentioned should be consulted and legal advice obtained.

In recent years the responsibilities for safety of persons at work have been prescribed in much legislation. The legislation of specific relevance to electrical maintenance is the Health and Safety at Work Act 1974, the Management of Health and Safety at Work Regulations 1999, the Electricity at Work Regulations 1989, the Workplace (Health, Safety and Welfare) Regulations 1992 and the Provision and Use of Work Equipment Regulations 1998.

The Health and Safety at Work Act 1974

Puts a duty of care upon both employer (sections 2, 3 and 4 etc) and employee (section 7) to ensure the safety of all persons using the work premises. This includes the self-employed.

The Management of Health and Safety at Work Regulations 1999

State: every employer shall make a suitable and sufficient assessment of the risks to the health and safety of his employees to which they are exposed whilst they are at work, and the risks to the health and safety of persons not in his employment arising out of or in connection with the conduct by him of his undertaking. (Regulation 3(1))

The Provision and Use of Work Equipment Regulations (PUWER) 1998 state:

Every employer shall ensure that work equipment is so constructed or adapted as to be suitable for the purpose for which it is used or provided. (Regulation 4(1))

PUWER only applies to work equipment used by workers at work. This includes all work equipment (fixed, portable or transportable) connected to a source of electrical energy. PUWER does not apply to the fixed installations in a building. The electrical safety of these installations is dealt with only by the Electricity at Work Regulations 1989.

The Electricity at Work Regulations 1989 state:

As may be necessary to prevent danger, all systems shall be maintained so as to prevent, so far as is reasonably practicable, such danger. (Regulation 4(2))

‘System’ means an electrical system in which all the electrical equipment is, or may be, electrically connected to a common source of electrical energy and includes such source and such equipment. (Regulation 2(1))

Electrical equipment includes anything used, intended to be used or installed for use, to generate, provide, transmit, transform, rectify, convert, conduct, distribute, control, store, measure or use electrical energy . (Regulation 2(1))

Scope of the legislation

It is clear that the combination of the Health and Safety at Work Act 1974, the Provision and Use of Work Equipment Regulations 1998 and the Electricity at Work Regulations 1989 apply to all electrical equipment used in, or associated with, places of work. The scope extends from distribution systems, be they 400 kV or simply those in buildings, down to the smallest piece of electrical equipment such as a hairdryer, a computer, a telephone or even in some situations battery-operated equipment.

Who carries the responsibility in law?

It shall be the duty of every employee while at work to co-operate with his employer so far as is necessary to enable any duty placed on that employer by the provisions of these Regulations to be complied with and to comply with the provisions of these Regulations in so far as they relate to matters which are within his control.

The Provision and Use of Work Equipment Regulations 1998

Requires every employer to ensure that equipment is suitable for the use for which it is provided (Regulation 4(1) and only used for work for which it is suitable (Regulation 4(3)). They require every employer to ensure equipment is maintained in good order (Regulation 5) and inspected as necessary to ensure it is maintained in a safe condition (Regulation 6).

This legislation applies to normal business, commercial and industrial premises such as shops, offices factories and workplaces.

It also applies to residential property let by private landlords.

Any loose connections or cord grips will be tightened during the testing included within the test price.

Any damaged plug tops will be replaced for £7.55 inc. parts and labour.

Any incorrect fuse sizes will be replaced for £1.50 as required. inc. parts and labour.

P.A.T TESTING COSTS DURING REGULAR WORKING HOURS:

We charge a minimum service fee of £80.00 which includes travelling, labour and certificates for the first 6 appliances to be tested. Further appliance tests are then charged at the following rates:

Up to 50 appliance tests: £4.50 per appliance

Up to 100 appliance tests: £4.25 per appliance

Up to 500 appliance tests: £4.00 per appliance

Up to 1000 appliance tests: £3.75 per appliance

If out of hours working is required then overtime rates as detailed on the homepage will apply.

P.A.T Testing

Mr Dilwyn Jones - Director of G-Force Ascot Ltd

Our specialised digital P.A.T tester is calibrated annually to ensure accurate results.